Aseptic

Fill-Finish & Lyophilization

Aseptic liquid filling in vials and pre-filled syringes is one of our core competencies. We specialize in modalities such as cell culture and microbial based proteins and enzymes, viral vectors, oncolytic viruses and monoclonal antibodies.

Broad Aseptic Contract Manufacturing Capability

IDT Biologika has nine filling lines with flexibility in vial sizes, volumes, speed and other parameters meeting the needs of virtually any type of product. We can fill sizes up to larger vials (e.g. 50R), but most vaccines are filled in vials from 2R up to 6R or 10R. We fulfill requests for vaccines at 0.3 ml or 0.2 ml or even below. We also have two lines for pre-filled syringes.

For aseptic filling, we continuously invest in technologies and capacities. As part of an investment of 80 million euros, we built a second, state-of-the-art high-speed isolator filling line in 2022. The filling line handles commercial batches with an effective output of up to 32,000 injection bottles per hour (2R) and 100% IPC of the fill weight.

Aseptic Vial Filling of Live Agents

As a leading vaccine and viral vector CDMO, IDT Biologika is distinguished from many biologics contract manufacturers by our experience and technology relating to production of live agents. Our facilities are GMP-compliant and manufacture to Bio Safety Level 2 (BSL-2), meeting FDA, EMA, and ANVISA standards, enabling us to lead the way in delivering finished dosage forms for live virus products.

The demands of avoiding any contamination are higher than usual with live agents, especially during changeovers since inactivation procedures need to be accomplished. We prefer to use single-use equipment including disposable mixing systems in areas with product contact. Our first isolator filling line currently handles only human active virus products, so there is no crossover with other biologics like recombinant proteins or bacterial vaccines. If sterile filtration is not applicable (e.g. for some larger viruses like MVA), we establish fully aseptic processing in open or closed systems, which is validated by Media Fills.

Small Scale to Large Commercial Volumes

Flexibility across our lines enables us to optimize filling processes across a wide range of vial sizes and batch volumes, meeting client needs from clinical to commercial supply. Our commercial filling lines can fill up to 32,000 vials an hour. Early clinical phase and small volume commercial product fills, such as cell and gene therapeutics, require small volumes even in commercial processes, so we make sure we can offer flexibility to meet every customer’s needs.

Our smallest filling line benefits from 100% IPC control of the filling weight, which is extremely important to customers, especially when their drug substance material is in very limited supply and is very expensive. In these cases, it is vital to mitigate product loss to only a few milliliters, which we can achieve through the precision of the equipment, automation and a single filling position, for example.

Capabilities

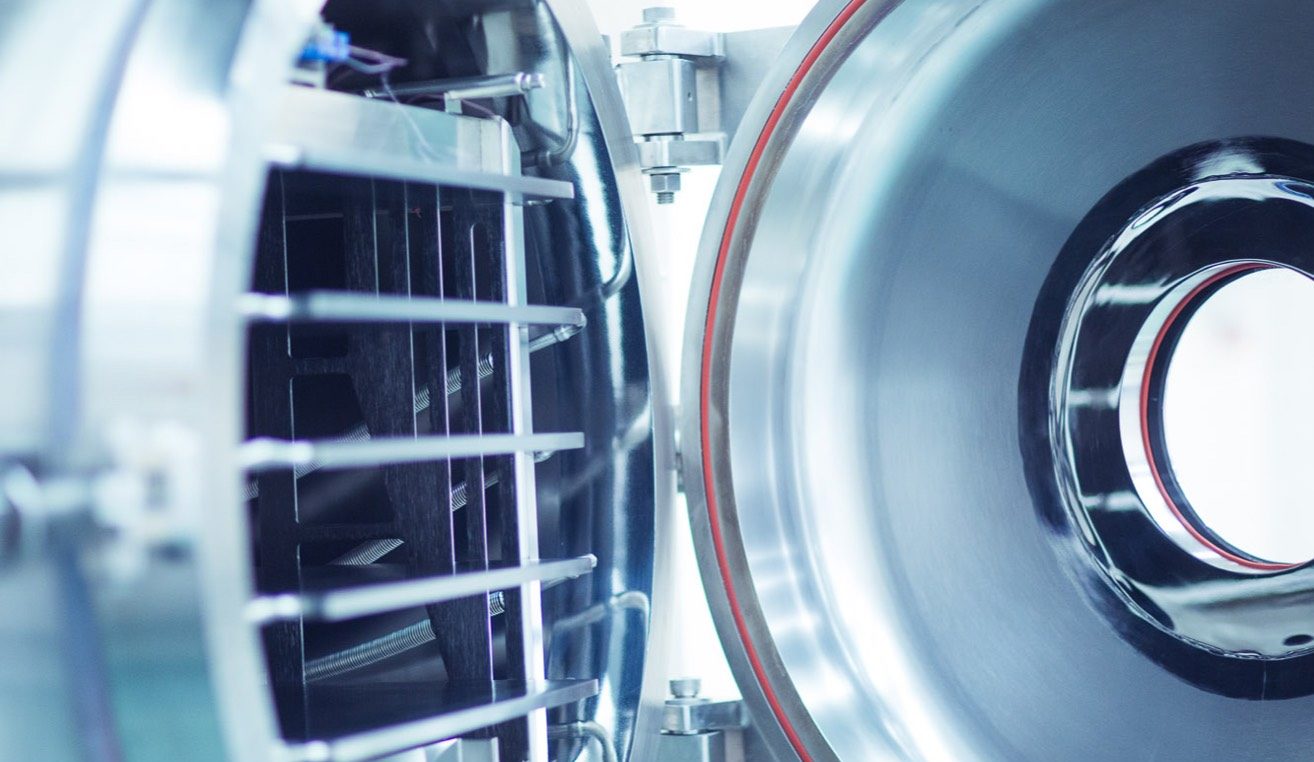

Lyophilization

Lyophilization is another area of strong competency and experience at IDT Biologika. We have lyophilizers on many of our aseptic filling lines, enabling us to offer lots of capacity for freeze-dried drug product. All lyophilizers are qualified for GMP production and the majority of lyophilized products go into 2R/2 ml vials. We have pilot-scale lyophilization with capacity of up to 3,000 vials, which can also be used for lyophilization process development.

Larger scale lyophilizers go up to 40 square meters, with capacity for 178,000 vials (2R). On the large-scale, commercial isolator filling line, we have up to three liquid nitrogen lyophilizers connected, equipped with common process analytical technologies (PAT). The lyophilizers are automatically loaded and unloaded.

With our expertise in vaccines, IDT Biologika has a lot of experience lyophilizing viral products, including live viruses. This specialization will become more important and grow in demand following the COVID-19 pandemic and the intensified focus on developing vaccines quickly and effectively.

Visual Inspection

Connected to our filling unit, we offer fully automatic, semi-automatic or manual inspection of vials with liquid and lyophilized contents as well as ready-to-fill syringes. The capacity of fully automatic sorting is up to 36,000 2R injection vials per hour.

Full-Automatic Visual Inspection:

- High-performance automated visual inspection unit

- Up to 36,000 vials 2R per hour

- Especially for large batch sizes and commercial supply

Semi-Automatic Visual Inspection:

- Vials (lyophilized)

- Vials (liquid) possible, but not established

Manual Visual Inspection for all formats:

- Vials (liquid)

- Vials (lyophilized)

- Syringes (liquid)

- Pens (medical device)

- Blisters